Plaster for Ceramics and Industry Use

There are various types suitable for different molding methods,such as slip casting, case molding, and original mold making.

Product Lineup

For General Ceramics

These products can be used for roller machines and slip casting, among other applications.

-

Special Grade Blue M

Fully automatic roller machine use

General roller machine use -

Special Grade Green

Fully automatic roller machine use

General roller machine use

Pressure casting use -

Special Grade KATSU

General casting use

Pressure casting use -

Special Grade Calcined Gypsum Green HF

General casting use

Pressure casting use

Industrial model use -

Grade A

General casting use

Molding use

For Casting

Suitable for aluminum casting and glass casting.

-

Caster 8

Vacuum casting for zinc and aluminum

Glass molding

Caster 8 reinforced with fiber -

Caster Y

Vacuum casting for zinc and aluminum

Glass molding

SSS Caster / Gypsum for Glass Molding

-

- What is the basic process for glass molding using the caster?Open

-

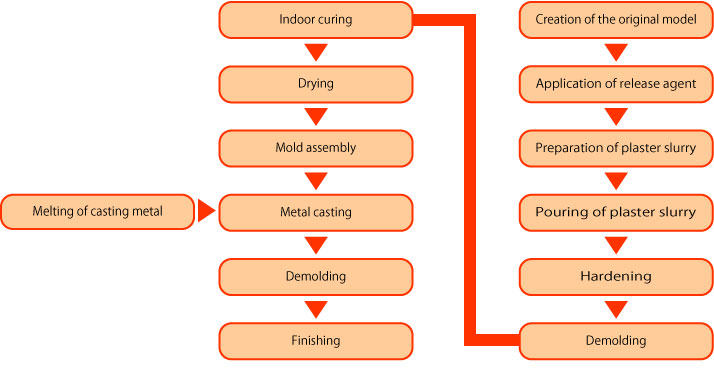

The basic procedure is as follows

- 1.Create a Model (rubber, clay, wood, etc.).

-

2.Create a Cavity (pour casting gypsum

and demold)

*Reinforce by tying the surroundings with wire.

*Mixing with ceramic fibers or SUS fibers is also effective. - 3.Add Glass Powder to the wet gypsum mold (from baby powder size to fist size, standard 40 mesh per inch).

- 4.Dry overnight at 150-200℃.

-

5.Heat gradually to 830-850℃ over 5-6 hours, for large items, hold for 1-2

hours.

(Note:Depending on the technique and glass conditions, 680-1000℃). - 6.Cool down to room temperature over 3 days for small items and 4 days for large items.

- 7.Deburr and polish.

- 8.Completion.

-

- What are the methods and processes for using the caster?Open

-

1.Creation of the original model

- Materials used: wood, plaster, silicone rubber, metal, etc.

- Note: Wood and plaster molds require water absorption prevention treatment with lacquer or varnish.

- Note: For original models with undercuts, use elastic materials like silicone rubber.

2.Release Agent

- Materials: machine oil, Vaseline, machine oil mixed with kerosene + stearic acid

- machine oil + (0.1 – 0.5%) methylene chloride

- Note: Excess release agent can cause bubbles in the final product.

- Note: Insufficient release agent can cause adhesion to the original model.

3.Water Mixing Ratio

- 50% (100 parts plaster + 50 parts water)

- Note: Use drinking water for the process.

4.Mixing

- Methods: hand mixing, mechanical mixing, vacuum mechanical mixing

(vacuum

mechanical mixing is the most

suitable). Mix for 4-6 minutes. Insufficient mixing can lead floatation and reduce strength.

Approximately 850 milliliters of mold can be made from 1 kg of caster.

5.Pouring

- Pour the mixture quietly into the original model after mixing. During this process, apply vibrations to the mold or

use a brush to raise bubbles to the surface of the mold.

6.Demolding

- Perform demolding when the mold temperature reaches its maximum.

Using compressed

air can make removal

easier.

7.Drying

-

Leave the mold indoors for about 3 hours after

demolding.

- From room temperature to 100℃: 1 hour

- From 100℃ to 150℃: 1 hour

- From 150℃ to 250℃: 1 hour

-

Note: Drying time can vary greatly depending on mold size, ventilation

in

the drying machine, number of molds

in the drying machine, and their placement within the drying machine. - Note: It is crucial to measure the temperature at the center of the mold using a thermocouple.

- Note: The mold is considered dry when the temperature at its center exceeds 200℃.

8.Casting

-

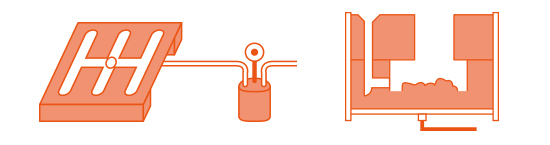

- What is the method for aluminum casting?Open

-

- Notes1: For reduced pressure: Depending on the shape of the product, please attach the same type of decompression device to the upper part as well.

- Notes2: The appropriate reduced pressure is 24-30 mmHg (a vacuum gauge is required).

- Notes3: The effective decompression time is the first 30 seconds immediately after casting, and it should be maintained for 2-3 minutes in general.

- Notes4: There is also a method to apply decompression to the entire mold after casting.

- In the drying machine, gradually lower the mold temperature to about 80℃ over more than 3 hours.

- Adjust the vacuum gauge reading to around 20-30 cmHg before casting.

- Notes5: The demolding time should be at least twice as long as that for sand molds.