Alpha plaster and beta plaster

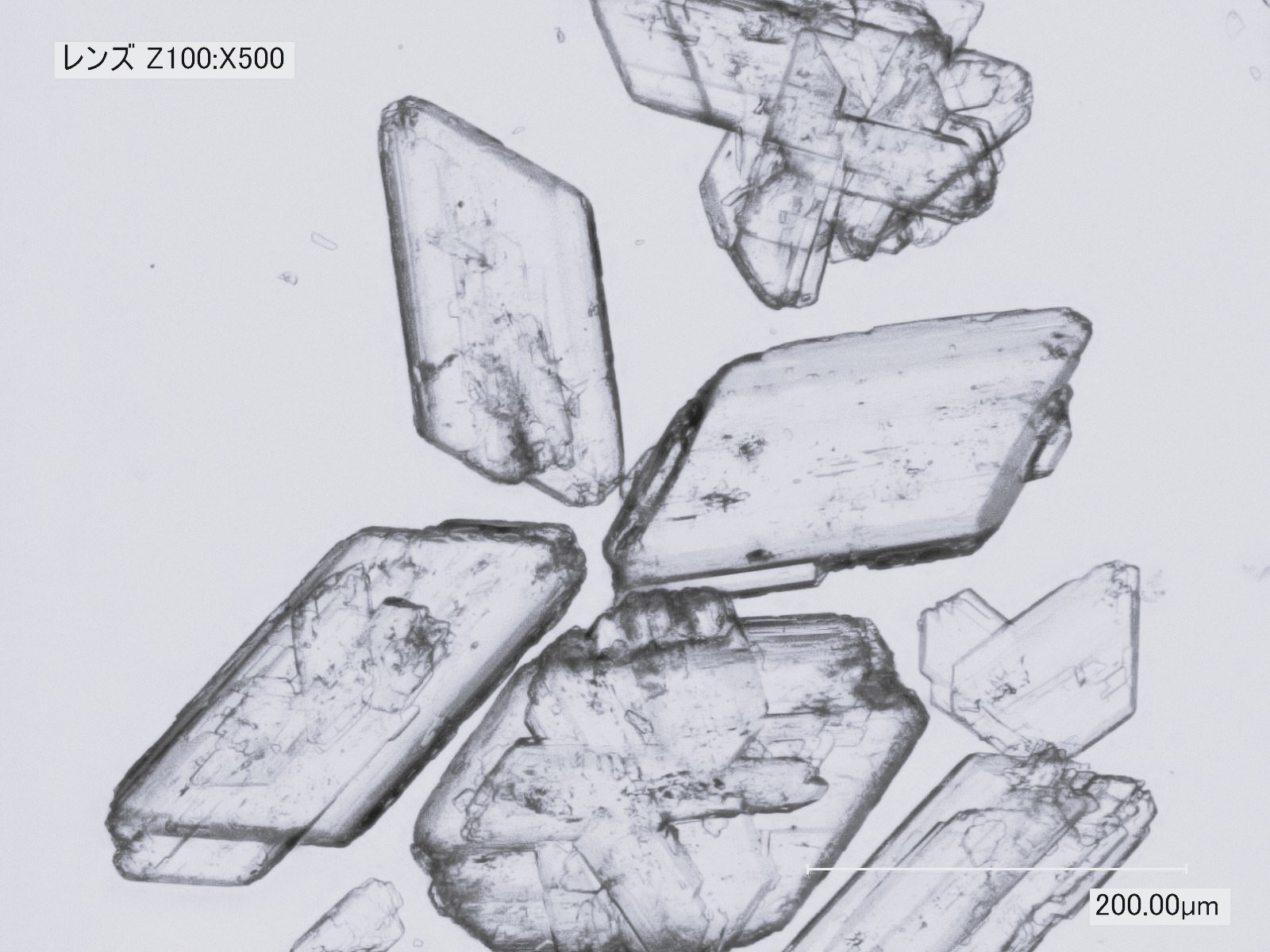

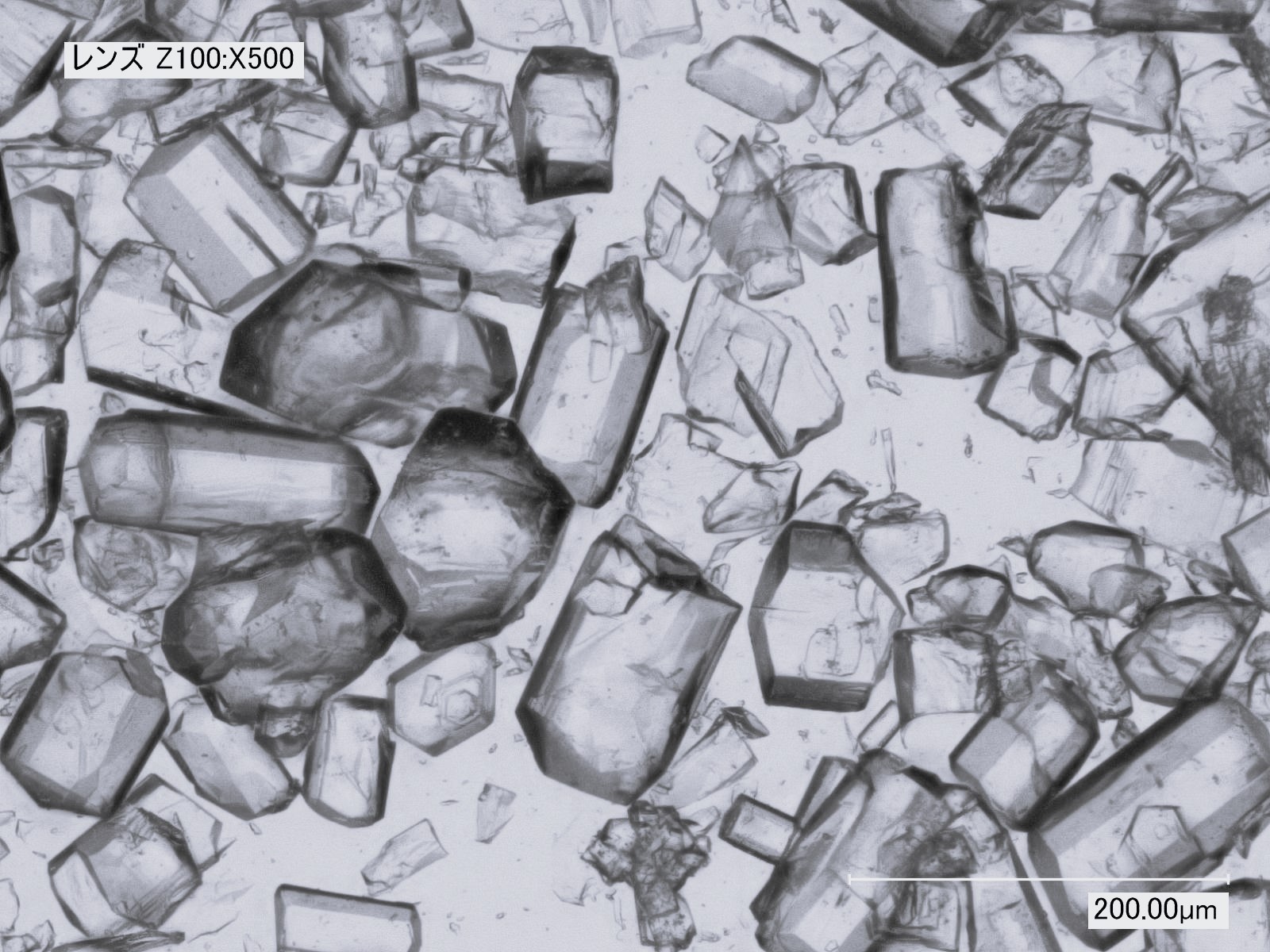

Alpha plaster is recrystallized in hot water after being pressure-heated in an autoclave.

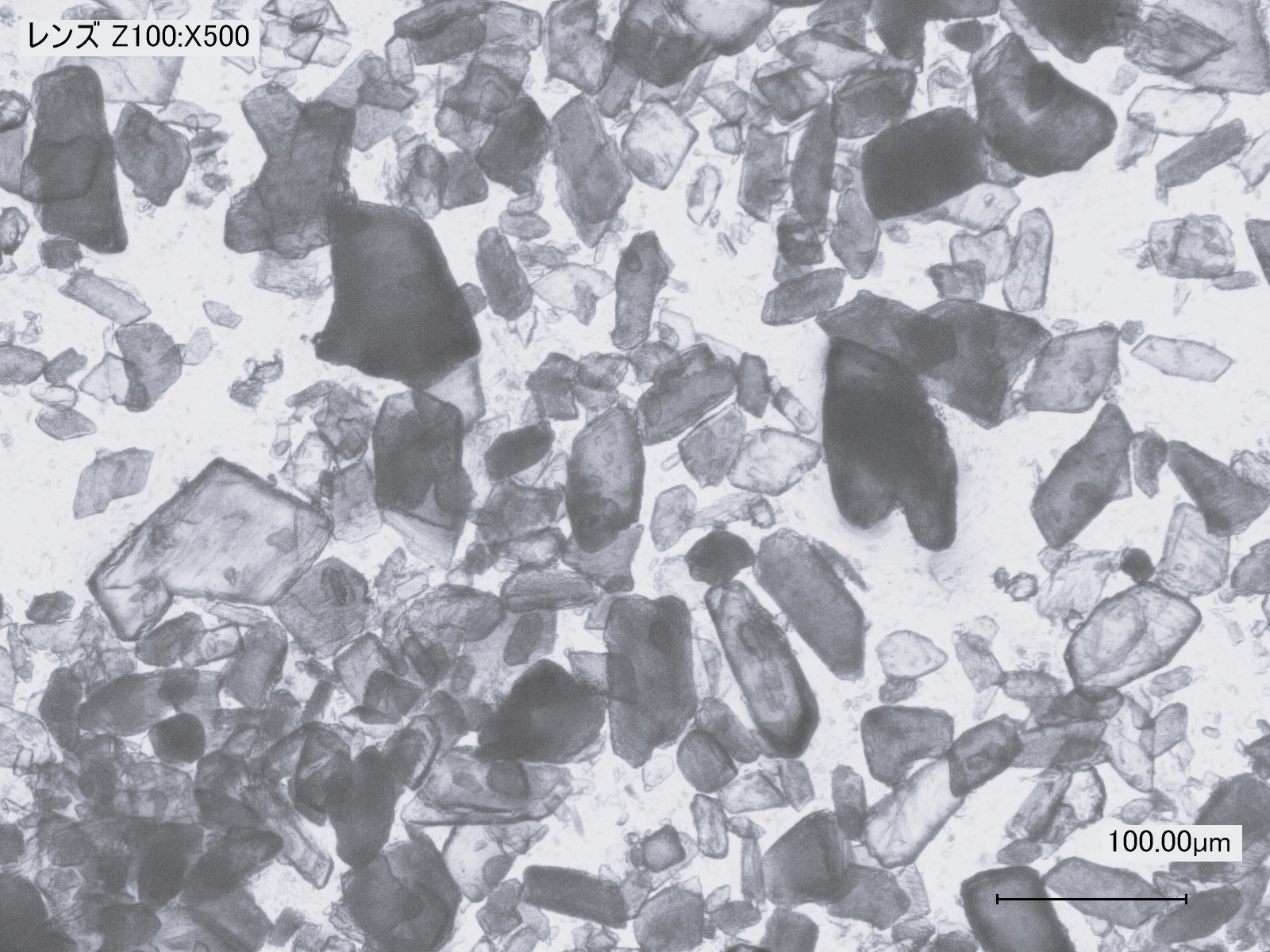

Beta plaster is obtained by heating raw dihydrate gypsum in the atmosphere, removing the crystal water while maintaining the crystal shape of the dihydrate gypsum.

Both alpha and beta plasters cannot be distinguished by X-ray analysis and have no difference in crystal structure; however, there is a significant difference in crystal shape.

Additionally, both alpha and beta plasters require the same theoretical amount of water for hydration per 100 grams.

However, alpha plaster becomes high-strength because it is dense and can be kneaded with a small amount of water.

Beta plaster, due to its porous crystal shape, requires more mixing water compared to alpha plaster, resulting in lower strength.

| Name/Chemical Formula | Alpha plaster | Beta plaster |

|---|---|---|

| Crystal System | Trigonal crystal | Trigonal crystal |

| Specific Gravity | 2.76 | 2.64 |

| Standard Water Mixing Ratio (%) | 35 | 90 |

| Setting Time (minutes) | 15~20 | 25~35 |

| Setting Expansion (%) | 0.28 | 0.16 |

| Wet Compressive Strength (kg/cm²) | 280 | 28 |

| Dry Compressive Strength (kg/cm²) | 560 | 56 |

| Manufacturing Method | Pressurized steam heating method Pressurized aqueous solution heating method |

Atmospheric heating method |