Dental Products

Leveraging our years of expertise and strong R&D capabilities, we provide safe and reliable dental products to meet our customers’ needs.

Key Products

-

Dental Die Stone TypeⅢ : Topstone DF

A dust-free type dental stone that produces a smooth and highly accurate impression model after curing. Packaged in 1.5kg bags, it is primarily used in dental clinics.

-

Alginate Impression Material : New Algistar

A highly precise alginate impression material that is easy to mix, spreads smoothly, and does not flow to the throat. The impression material does not adhere to the teeth, making it friendly for both users and patients.

-

Dental Products : Daichan Series

An innovative adhesive model base developed to achieve an economical and precise technical system. Simply attach the impression model to the pre-made base to complete the model.

-

Dental Products : AL Remover

A liquid tray cleaner designed to shrink and peel off alginate impression material. It offers quick processing without dissolving, leaving no sediment, and has antibacterial properties.

-

Dental Product : Chlor Anchor

A hygienic solution for thorough disinfection in places where cleanliness is essential. Using Chlor Anchor in accordance with standard precautions enhances hygiene management in the clinic.

Product Lineup

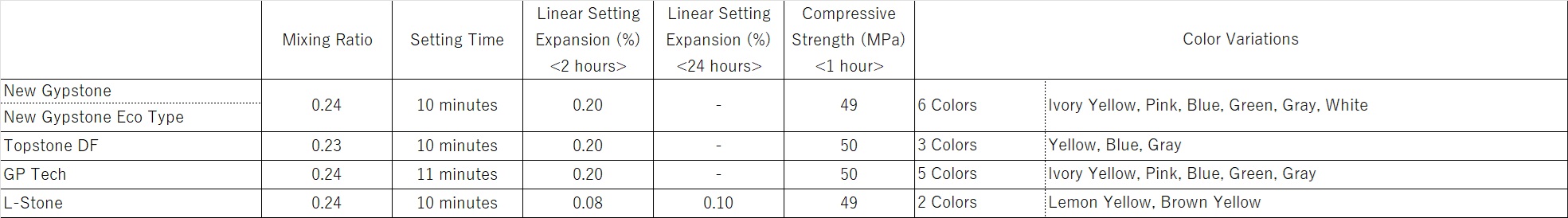

Dental Die Stone TypeⅢ

We offer a range of dental gypsum products, including general-purpose, technical use, dust-free, and low-expansion models.

-

New Gypstone, New Gypstone Eco Type

Suitable for various models such as inlays, crowns, bridges, partial dentures, complete dentures, and orthodontic models.

-

Topstone DF

Suitable for various models such as inlays, crowns, bridges, partial dentures, complete dentures, and orthodontic models.

-

GP Tech

Suitable for various models such as inlays, crowns, bridges, partial dentures, complete dentures, etc.

-

L-Stone

For low-expansion models such as inlays, crowns, bridges, etc.

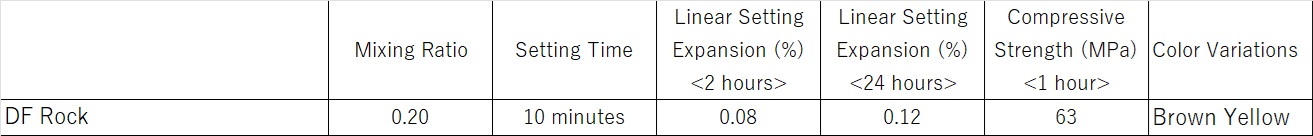

Dental Die Stone TypeⅣ

Dust-free type ultra-hard gypsum that produces more dense and smooth model surfaces with various impression materials.

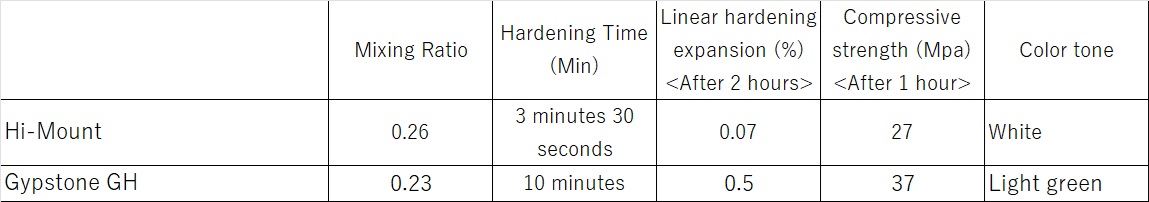

Dental Stone for Special Use

Includes ultra-fast hardening, low-expansion gypsum for articulator mounting, and high-expansion gypsum for resin denture models.

Frequently Asked Questions

-

- Is there an expiration date for these products?Open

- Unopened products have a shelf life of 3 years in aluminum packaging and 2 years in paper bags. Once opened, store in an airtight container and use promptly to prevent moisture absorption and quality issues. You can check the expiration date of your product by looking at the numbers (year, month) following the hourglass mark (⌛) above the barcode on the product.

-

- Are there specific measuring tools available?Open

-

No.

We recommend measuring by weight.

Measuring gypsum by volume can lead to inconsistent performance.

By weighing it, you can ensure consistent performance for anyone using it.

-

- Can salt be added to accelerate hardening process?Open

-

It is not recommended to use salt.

Instead, increase the water temperature or the number of mixing cycles to speed up hardening.

-

- Is there a white ultra-hard gypsum?Open

- No.

-

- Is there a fast-setting type available?Open

-

We do not have a fast-setting type that begins initial hardening in about

5 minutes.

However, Hi-Mount, designed for articulator mounting, hardens in 3 minutes and 30 seconds and can be used as an alternative.

-

- How can surface roughness on gypsum models be addressed?Open

-

Surface roughness is often caused by delayed or insufficient hardening.

Ensure precise weighing and mixing times, and follow specific steps to

address potential issues from impression materials and handling techniques.

Here are the main causes and solutions:

-

Cause 1:

Some additives in alginate or agar impression materials can delay the curing of gypsum. Over time, these additives may seep onto the impression surface (a phenomenon known as syneresis), leading to insufficient curing and resulting in surface roughness on the gypsum areas that come into contact with the impression.Solution 1:

- 1. Immediately rinse the impression surface with running water after taking the impression and shake off the excess water.

- 2. For alginate impression materials, spraying with Smooth Maker can be beneficial.

- 3. Avoid leaving the impression exposed indoors for an extended period.

-

Cause 2:

Some surfactants used in silicone impression materials (to prevent bubbles) can delay the curing of gypsum. When a significant amount of these surfactants remains on the impression surface, particularly in corner areas, the gypsum may not cure properly, resulting in surface roughness.Solution 2:

- After using silicone impression materials, remove the surfactants by washing with water and then using air or similar methods to ensure thorough removal.

-

Cause 3:

Saliva and blood contain components that can delay the curing of gypsum. If these contaminants remain on the impression surface, they cause insufficient curing and surface roughness in those areas.Solution 3:

- 1.Remove saliva and blood using a soft brush.

- 2.Use tissue paper twisted into a wick shape to absorb excess water from the corners.

-

Cause 4:

If water remains on the impression surface after washing, it can prevent the gypsum from forming a dense structure, leading to surface roughness. Additionally, prolonged contact with water after curing can cause the gypsum to dissolve from the surface, resulting in roughness.Solution 4:

- 1.After washing the impression, use air or similar methods to remove the water.

- 2.Use tissue paper twisted into a wick shape to remove excess water from the corners.

-

Cause 5:

Using a trimmer or steam cleaner on gypsum that has not fully hardened will cause surface roughness as it flakes off from those areas. A complete hydration reaction for gypsum requires 2 hours for regular gypsum and 3 hours for hard gypsum.Solution 5:

- 1.Allow the gypsum model to set in a place where it won’t dry out for at least 2-3 hours before handling.

- 2.Use a dry trimmer. If using a wet trimmer, cover at least the tooth model parts with wax.

- 3. Avoid using a steam cleaner on the tooth model parts.

-

Alginate Impression Materials

New Algistar mixes well with water and produces clean, accurate models.

Investment Materials

Suitable for casting non-precious metal crowns, bridges, inlays, and metal bonds.

Other Dental Products

We also offer adhesive model bases, gypsum dissolving solutions, and other hygiene products.

-

AL Remover

Liquid cleaner for dental alginate impression material.

-

SAN ESU Tray Cleaner

Powder cleaner for dental alginate impression material.

-

Chlor Anchor

Disinfectant and fixative for dental impressions.

-

Smooth Maker

Lubricant for dental impressions.

-

Daichan Series

Adhesive model bases.

-

SAN ESU Disk W

Dental casting wax.

-

Quick Melty

Gypsum dissolving solution.

-

My Sep

Separator for dental resin bases.

-

.jpg)

Super Electrolyzed Water Clean Shu! Shu!

Alkaline ionized cleaning water.

-

SSS Multi Powder Box

Storage container for various gypsums and powder impression materials.